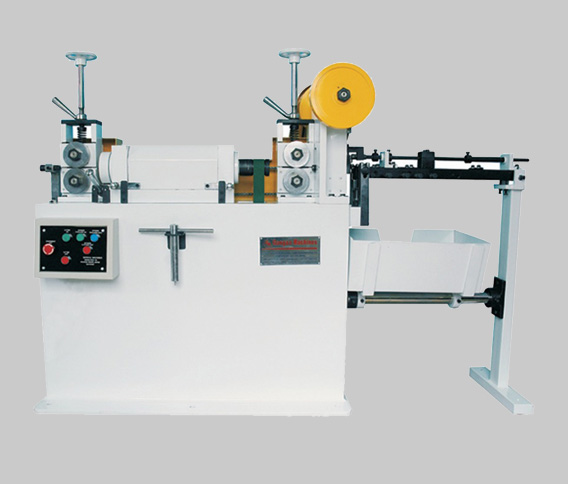

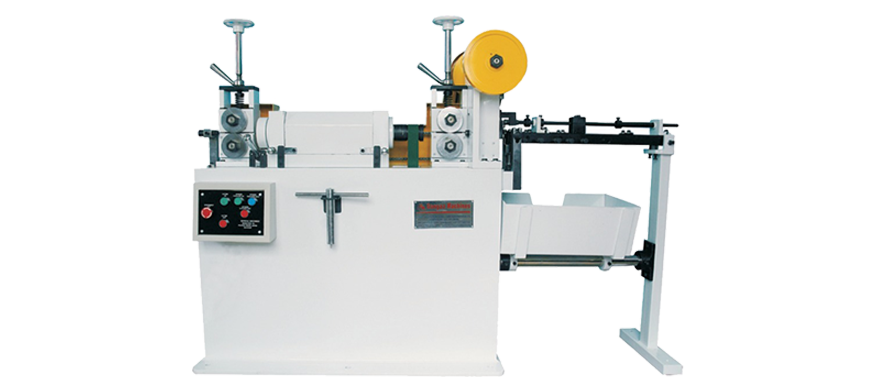

ASSOMAC provides advanced wire straightening and cutting machines designed to handle wire in coils or spools, capable of cutting rods to the specified length. Our machines accommodate ribbed wire sizes ranging from 4.5 mm to 20 mm and regular wire sizes from 1.6 mm to 20 mm. Each machine features an entry guide roll box, pre-tensioners, and adjustable multi-roll straighteners configured in both horizontal and vertical axes. It is equipped with a pneumatic clutch activated flying shear, a double collection station magazine with a capacity of up to 12 meters in length, and pneumatic actuation with automatic piece counting. Centralized control is facilitated through a multi-PLC based display unit that indicates the operational status.

Wire Straightening & Cutting Machine

Overview

ASSOMAC provides advanced wire straightening and cutting machines designed to handle wire in coils or spools, capable of cutting rods to the specified length. Our machines accommodate ribbed wire sizes ranging from 4.5 mm to 20 mm and regular wire sizes from 1.6 mm to 20 mm. Each machine features an entry guide roll box, pre-tensioners, and adjustable multi-roll straighteners configured in both horizontal and vertical axes. It is equipped with a pneumatic clutch activated flying shear, a double collection station magazine with a capacity of up to 12 meters in length, and pneumatic actuation with automatic piece counting. Centralized control is facilitated through a multi-PLC based display unit that indicates the operational status.

Specification

Technical Specifications

| Model No | AML-SC-03 | AML-SC-05 | AML-SC-08 | AML-SC-16 | AML-SC-ES (Electrode Special) | AML-SC-R8 (Ribbed Special) | AML-SC-R12 (Ribbed Special) |

| In Thickness of Wire | 1.6 to 3 mm | 2.5 to 5 mm | 4 to 8 mm | 8 to 16 mm | 3 to 5 mm | 4 to 8 mm | 6 to 12 mm |

| Length of wire to be cut automatically | 0.3 to 2.5 mtrs. | Upto 6 mtrs. | Upto 6 mtrs. | Upto 6 mtrs. | 350 to 450 mm | Upto 12 mtrs. | Upto 12 mtrs. |

| Capacity per min. (Max.) | 36 mtrs./min. | 60 mtrs./min. | 50 mtrs./min. | 20 mtrs./min. | 50 mtrs./min. | 140 mtrs./min. | 140 mtrs./min. |

| Power of Motor Required (H.P/R.P.M) | 3 + 1 HP / 1440 | 7.5 + 1 HP / 1440 | 10 + 1 HP / 1440 | 15 + 2 HP / 1440 | 5 + 1 HP / 1440 | 15 + 2 HP | 25 + 3 HP |

| Approx Weight | 450 kgs. | 550 kgs. | 650 kgs. | 2000 kgs. | 600 kgs. | 2400 kgs. | 2800 kgs. |

| Floor Space required (In Feet) | 3’ x 18’ | 3’ x 30’ | 3’ x 30’ | 7’ x 80’ | 4’ x 15’ | 8’ x 80’ | 8’ x 80’ |

| Pay-Off Stand | Revolving Pay-Off for 300 kgs. coil weight | Revolving Pay-Off for 300 kgs. coil weight | Revolving Pay-Off for 300 kgs. coil weight | Turn-Table Pay-Off for 1500 kgs. coil weight | Revolving Pay-Off for 300 kgs. coil weight | Turn-Table Pay-Off for 1500 kgs. coil weight or horizontal spool Pay-Off | Turn-Table Pay-Off for 1500 kgs. coil weight or horizontal spool Pay-Off |